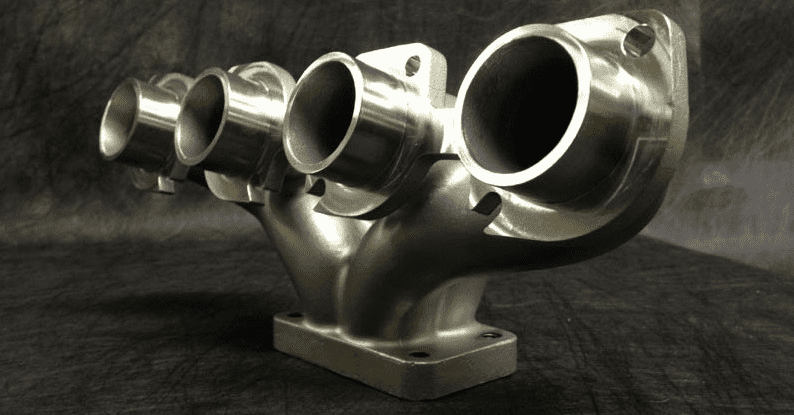

Silicon sol investment casting uses a lost wax process to create intricate shapes and designs that are difficult to achieve with other methods. This process involves creating a wax pattern of the desired part, which is then coated in a ceramic shell. The wax is melted out of the shell, and the resulting cavity is filled with molten stainless steel. Once the metal solidifies, the ceramic shell is broken away, leaving behind a finished casting.

Precision casting, also known as investment casting, is a similar process that uses a wax pattern but differs in the way the metal is poured into the mold. In precision casting, the wax pattern is also coated in a ceramic shell, but the metal is poured into the mold using a centrifugal force. This allows for more consistent and precise castings.

Both silicon sol investment casting and precision casting have their advantages for creating casting steel parts for fire protection. Stainless steel is a popular choice for these parts because it is corrosion-resistant, durable, and can withstand high temperatures. Castings made using these methods are also highly precise, making them ideal for complex designs that require tight tolerances.

The benefits of using casting steel parts for fire protection are numerous. They are capable of withstanding extreme conditions, which is crucial in fire protection applications. They also have a longer lifespan than many other materials, reducing the need for frequent replacement. Additionally, casting steel parts can be produced in large quantities, making them a cost-effective solution for high-volume production.

In conclusion, stainless steel silicon sol investment casting and precision casting are two methods used to create casting steel parts for fire protection. Both methods produce high-quality, precise parts that are ideal for use in harsh environments. By investing in casting steel parts, businesses in the fire protection industry can improve the safety and reliability of their products while also reducing costs associated with frequent replacement.